Project Description

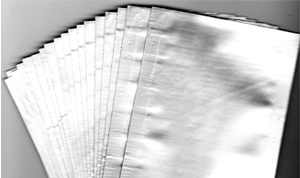

If your cargo is precious then using traditional polythene film is doing more harm than you expect as it easily permits moisture, odour, oxygen, corrosion, UV radiation, acids, alkalis from outside resulting in loses of aroma & product-life. Aluminium vacuum packing foils is ideal for protecting moisture-sensitive products from corrosion during transit and storage.

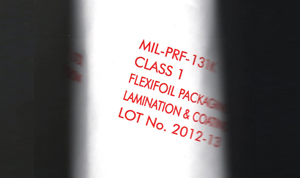

FFPPL offers Flexi-Vac –a specially designed range of multilayer laminates consisting of high-strength Polyester Film, Aluminium Foil, BON & Co-extruded polymer designed to give excellent barrier properties, delivering to your customers a product as good as at point of manufacture. It is manufactured from flexible polymer and aluminium laminates and provides a flexible barrier with a very low rate of vapour transmission.

Flexi-Vac films have water vapour transmission rate of 0.05gm per m2 per 24 hours which rate is 20 times lower than heavy duty 500 gauge polythene and 80 times lower than 125 gauge polythene and also provide excellent protection against damage from biological sources, ultraviolet light, acids, alkalis and odour transfer.

Box Type Bags *Jumbo Bags *4-D Bags *Printed Bags *Three Side Sealed Bags

Common Structures

- Polyester Film – Aluminium Foil – LDPE

- Polyester Film- Aluminium Foil – Polyester Film – LDPE

- Polyester Film – Aluminium Foil – Nylon – LDPE

- Polyester – Metallised Polyester Film – LDPE

Product Features

- Extended Shelf Life

- Superior Tear and Puncture Resistance

- Allows Outdoor Storage

- Hermetically Sealed, No stitching Or Gluing

- High Quality Product Presentation

- Available in Rolls / Bags

- Excellent protection against Moisture/Oxygen Transmission / Corrosion / Physical Damage /Odour Transfer / UV Radiation etc

- Corrosion is kept at a bay by maintaining humidity level below 40 RH.

- Overall cost reduction by way of reduced desiccant/preservatives, packing case cost and rejections due to corrosion and spoilage of packed products.

- Strong Customer loyalty on repeat purchase

- Highly effective odour barrier

- Cost-effective packaging solution, due to the desiccant reduction required in comparison to a polythene based solution; this in-turn may lead to lower freight costs.

Applications

Pharmaceuticals and Bulk Drugs/Machinery Packaging /X-ray machines/Optical and Electronic instruments/Engines and Transmission assemblies/Transformers/Defence and Aerospace /Chemicals and Dyes /Foodstuffs /Rubber Compounds/ Polymer Granules/Computers Food ingredients / flavours / Tea/Coffee / Cocoa Powder / Dried Foods/ Polymers / Resins / Chemical & Pharmaceuticals / Dyes / Pigments /Animal feeds etc.

SERVICE INFO

OTHER PRODUCTS

General Packaging

Spices, Instant Food, Snacks, Cereals, Food Mix & Additives, Dry & Frozen Foods, Grocery, Pulses, Pickles, Atta Flour.

Moisture Barrier Packaging

Aluminium Foil Vacuum Packing, Moisture Barrier Bags, 4D Bags, Liners, Pouches, Export Packing, Industrial Packaging.

Aluminium Foil Packaging

Strip Foils, Blister Foils, Child Resistant Foils, Cold Form Foils, Alu Alu Foils, High Performance Blister .

Customised Packaging Solutions

Different structure of the films providing optimum mechanical and barrier properties can be engineered based on the buyer’s requirement.

Pre Formed Pouches

3-Side Sealed, Center Bottom Sealed, Side Gusseted, Stand Up, Stand Up Zipper, V-Notch, D-Punch, Zipper, Round Cornered.

Aluminium Lidding Foils

FFPPL offers a wide range of lidding solutions that can meet the pharmaceutical market’s demand for high quality products.

FREE QUOTE

Do you need help with

Flexifoil Packaging

maintenance? Fill out this form to get in touch.

Error: Contact form not found.

Error: Contact form not found.